Page 13

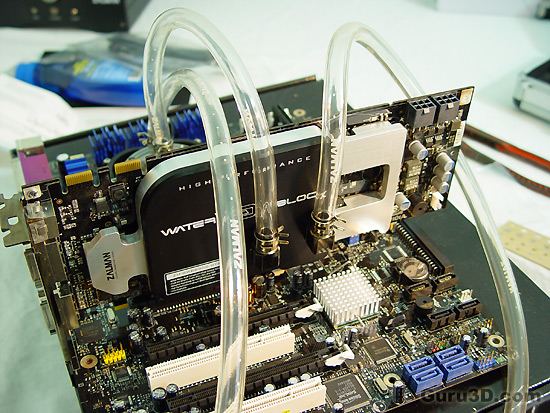

We now insert the graphics card.

Now have a look at our flow line. This is something you will need to determine before installation of course.

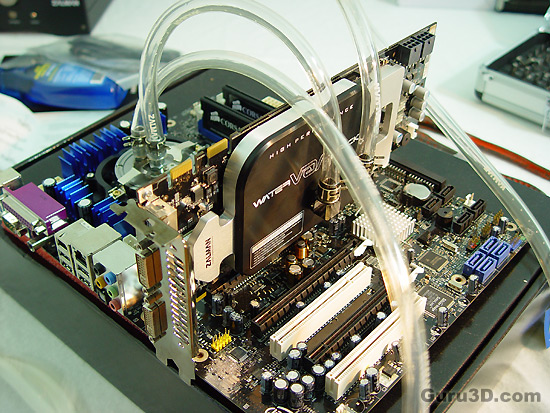

The flow should go from the Reserator towards the CPU, then towards the GPU and then back to the Reserator. Try to work the flow from up to downwards, gravity, make it as easy on the pump as possible. Don't forget to guide the tubing into the casing with the help of the I/O bracket. You guide the tubing to the water units and then lead them outside the system case through the holes in this special back panel bracket. Also a power cable goes inwards that connects to a Molex connector as it's being used to power up the Reserator.

Okay this is good enough for our test; we are ready to go. We now need to check and fill the Reserator unit itself.

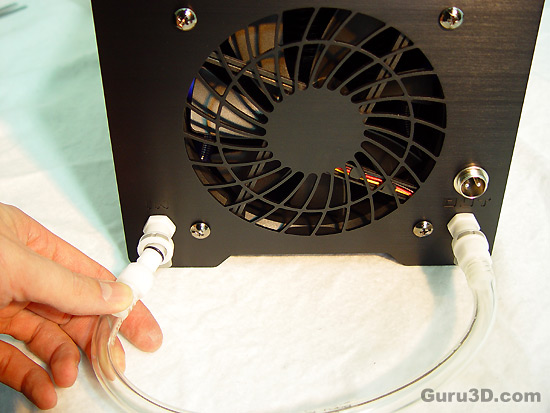

The first thing you need to do is connect the degassing tube. There's air inside the Reserator we need to get rid of before it's pushed into meters of tubing and the water-blocks. These connectors are brilliant, they just do not leak. Example; if you remove them from the Reserator, well, they're closed, so no water will spill out of the Reserator or even the tube itself once disconnected. We have an inflow and an outflow. Simply push them into the Reserator and we are almost done here.

Since we established and setup the flow line and thus entire water circuitry, we are going to do a double-check to see if everything was fitted properly and that you have your flow-line optimised.

Do not hook up your PC towards the rest of the peripherals or PSU. We'll test functionality of the Reserator only before we turn on the PC by using a bypass.

Now we'll add the supplied Anti-corrosion Coolant, ZM-G300. The Anti-Corrosion Coolant supplied with the Reserator XT has been designed to prevent corrosion not only to the Reserator but also other materials it comes into contact with, such as copper, aluminum and plastic. This provides peace of mind for long-term operation.