Graphics Card Thermal Imaging Measurements (FLIR)

Thermal Imaging Temperature Measurements

A new addition to our reviews will be the inclusion of Forward Looking Infra Red thermal images of hardware. Over the past years we have been trying to figure out the best possible way to measure temperatures on hardware. Multiple options are available but the best thing to do is to visualize heat coming from the product or component being tested. The downside of thermal imaging hardware is simple, FLIR cameras with a bit of a decent resolution cost up-to 10,000 EUR. Hence we passed on it for a long time.

With a thermal imaging camera a special lens focuses the infrared light emitted by all of the objects in view. This focused light is scanned by a phased array of infrared-detector elements. The detector elements create a very detailed temperature pattern called a thermogram. It only takes about one-thirtieth of a second for the detector array to obtain the temperature information to make the thermogram. This information is obtained from several thousand points in the field of view of the detector array. The thermogram created by the detector elements is translated into electric impulses. The impulses are sent to a signal-processing unit, a circuit board with a dedicated chip that translates the information from the elements into data for the display. The signal-processing unit sends the information to the display, where it appears as various colors depending on the intensity of the infrared emission. The combination of all the impulses from all of the elements creates the image.

Why A Move Towards Thermal Imaging?

A new trend e.g. cheat is that manufacturers are tweaking their products with another offset, meaning that sometimes (and we have seen this only a couple of times) the temperature reported back by monitoring software often was lower than the product in reality is. With thermal imaging this becomes a thing of the past as we can seek hotspots on the PCB indicating for example GPU but also VRM temperature as well as how heat is distributed throughout a product. We do hope you will enjoy this new technology as it did cost us an arm and a leg to be able to implement it.

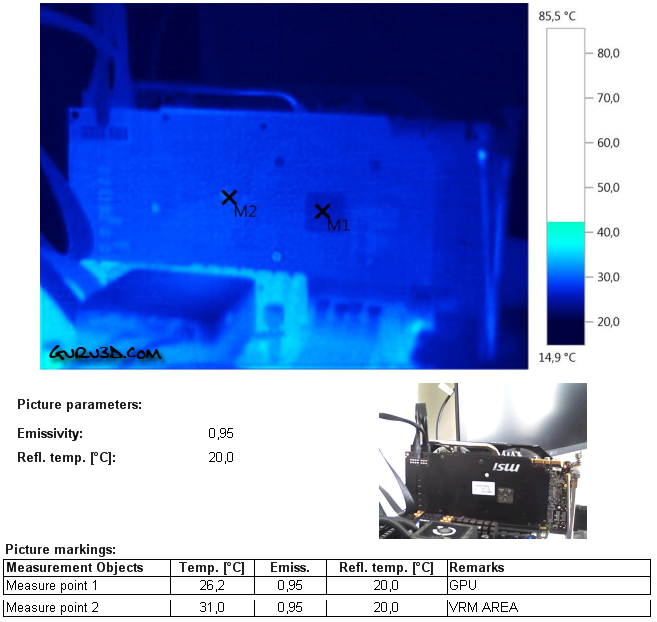

Above, you can see the graphics card in IDLE conditions on air cooling. We position our measurement point in the GPU die area at the backside of the PCB. Roughly 30 degrees C at the GPU area. The VRM area is at 31 Degrees C, even with the PC in idle.

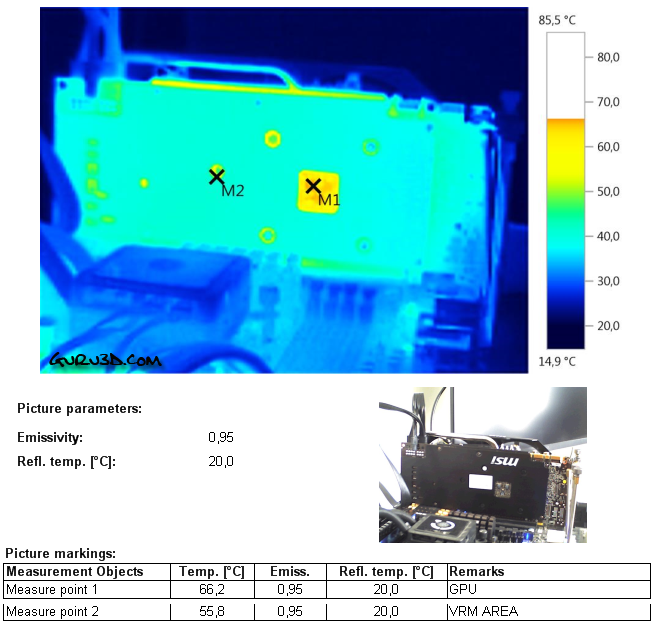

Once we start to stress the GPU the thermals change. We can measure thermals to the 10th of a degree precise really, our thermal camera is calibrated and does not lie. We reach 65~70 Degrees C on the GPU. The VRM area is located closer to the rear of the card where it is cooler, they run at roughly 55 to 60 Degrees C. Hard to measure due to the back-plate though, we have this tiny gap of a screw hole where we can just reach the VRM area. Not ideal, so consider that one to be more of an indication opposed to a precise measurement.

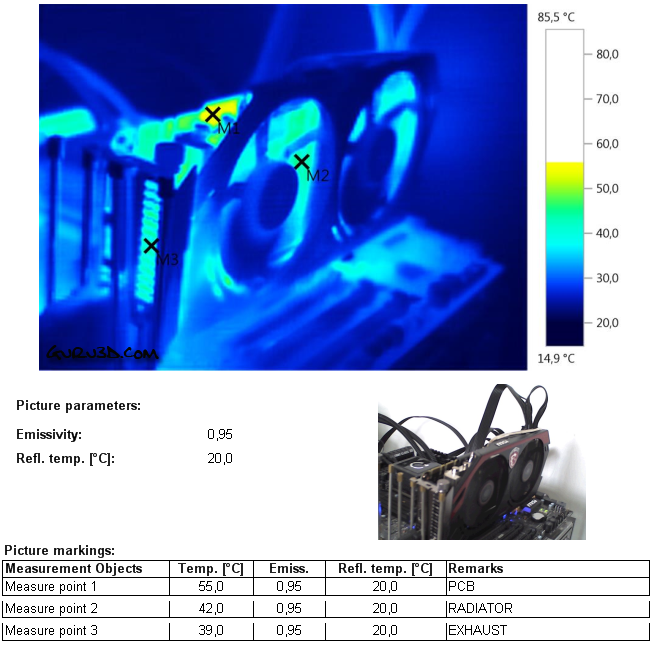

When we position the thermal camera outwards we can see that the cooler really works well. The hottest point is the top side of the card where there is some residual PCB heat detected. Overall I am very pleased with what we see here as the cooler seems to manage and exhaust hot air reasonably well. That VRM area could use better cooling though.