The Motherboard DIP line

One last final check here. This employee makes sure that all components are inserted and placed properly. Also a little weight is added to the bigger parts like the processor socket as they could actually float a little in the wave soldering machine.

To your left you can see that final step of the DIP process. Here the motherboards enter a wave soldering machine where all components are soldered shut. So it will pretty much run the bottom of the motherboard or VGA card through a 'wave' of liquid solder at a pre-determined height. This way all the metal pins of the components that were just inserted are coated with solder.

In this machine the pin-through components are electrically and mechanically connected in one step, here they are solder dipped. But of course, we are not yet ready...

The boards thereafter go onwards to QA where testing is done. We noticed a lot of QA points in the entire production line. Everything is registered checked, double checked and even triple checked.

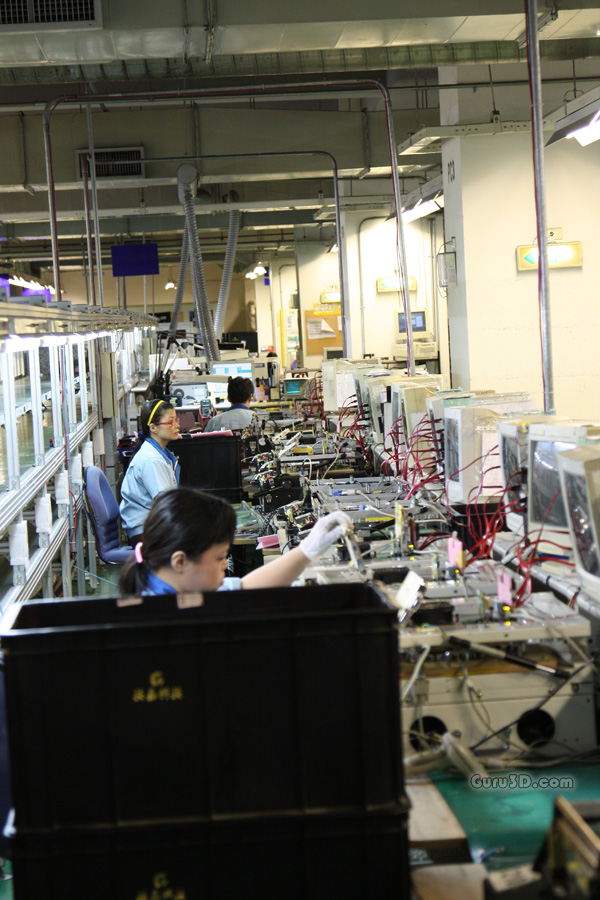

There however was a second production line running.