The Motherboard DIP line

As you can imagine, a lot of components require a lot of staff. A motherboard takes a long production line with a lot of personnel. It is pretty much a large conveyor belt taking the product from point A to Z. As you can understand, do that a couple of weeks and you'll be bored to death. Gigabyte therefore rotates the station on a very regular basis.

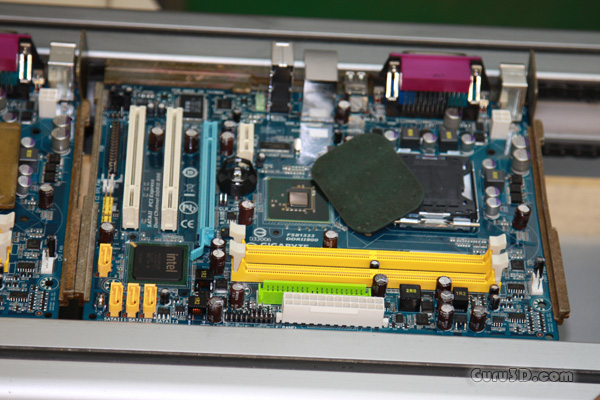

In the last stage of the line the bigger parts of motherboard assembly are applied like I/O ports... again all by hand.

All components have now been applied and mounted. But they sit loosely on there. Of course they need to be soldered onto the PCB. Since manual soldering would be horribly time consuming, complicated and inaccurate, Gigabyte makes use of a unique soldering process called wave soldering.