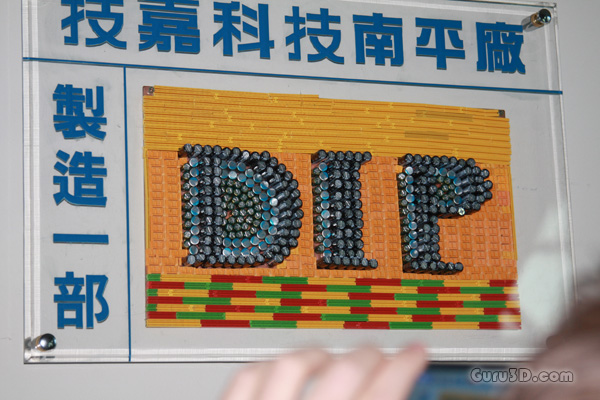

The Motherboard DIP line

The Motherboard DIP line

We now go down a floor and enter a new hall. The DIP lines are located here. And that sign really explains it all. Dual In-line Package (DIP). See, the next step in bringing these PCB motherboards and graphics cards to life involves an assembly line where all the components that need to be plugged into the pre-drilled holes in the board are added. What most people do not know... that this is all about manual labor... a lot of it.

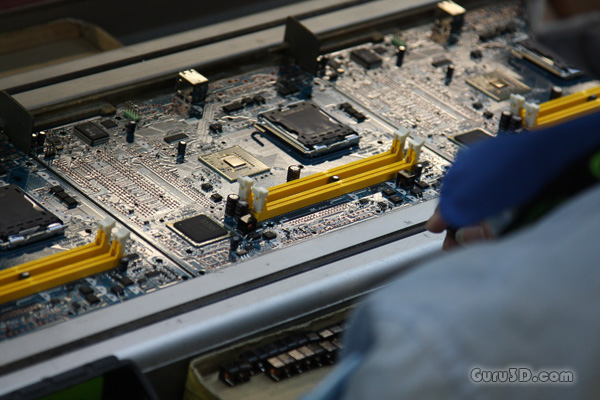

We follow the process here with a motherboard first. After the PCB was prepped with SMD components and motherboard chipset, the PCB needs the residual DIP components. Check above, you can see that's an empty motherboard right?

Here sound I/O mountings and two DIMM slots have just been inserted, these are the DIP components, the second stage gear.

Each employee now adds 3 to 5 components per passing motherboard. These can be the DIMM slots, resistors, capacitors, chokes, whatever it needs.

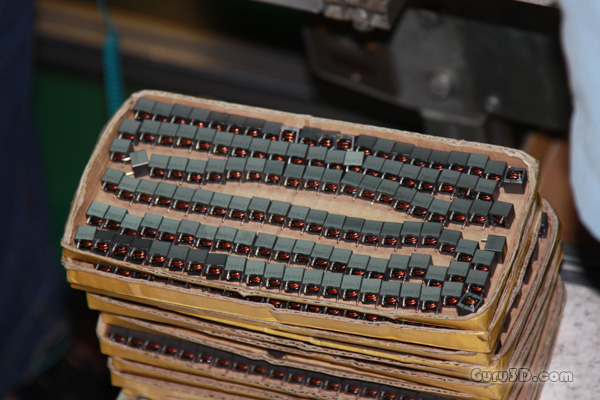

Ferrite core chokes anyone? Part of Gigabyte's Ultra Durable products of course. Piece by piece they are stuck into the PCB, by hand.